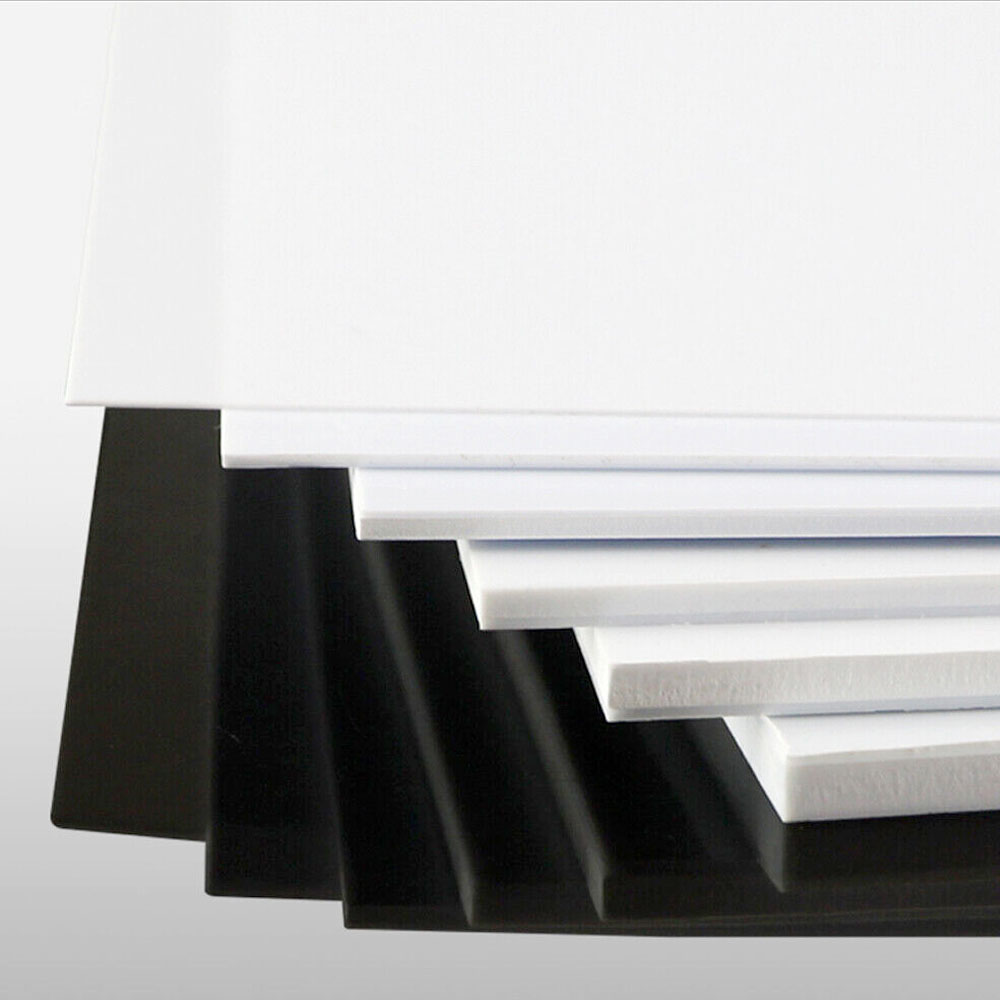

Customized Thermoforming Service

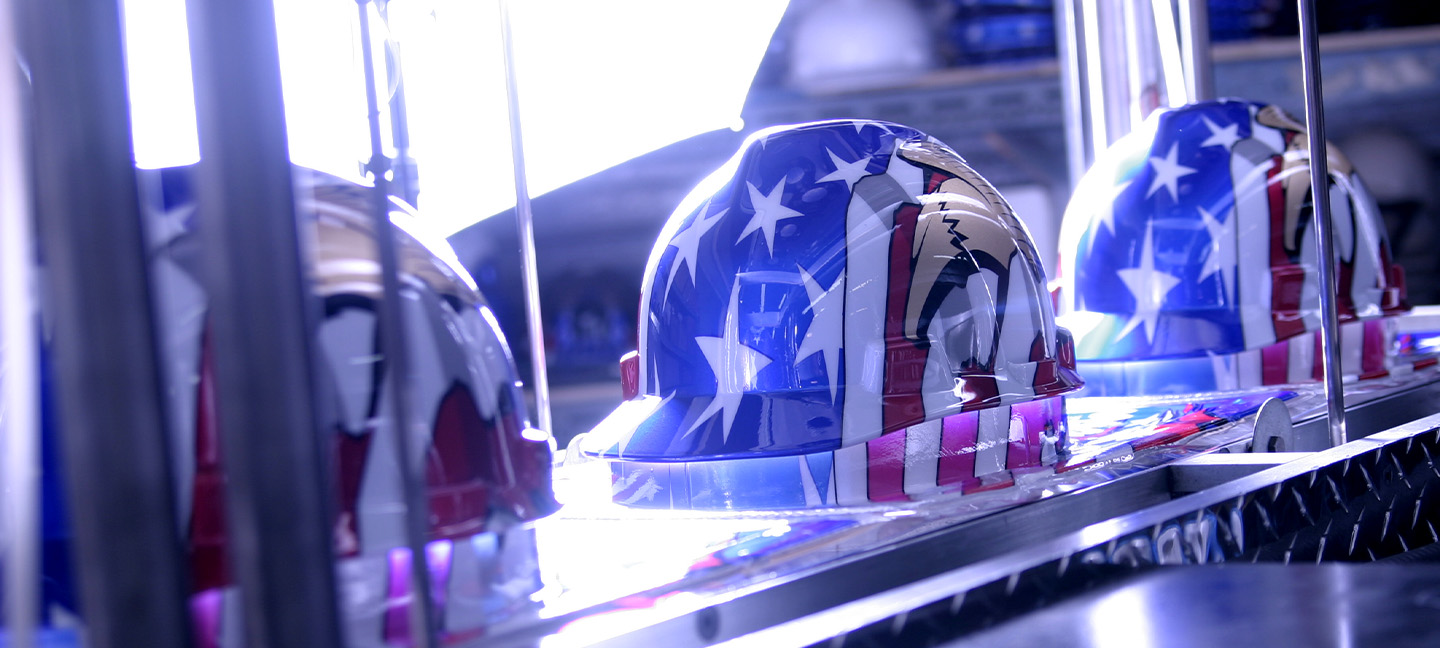

The advantages of opting for Serico’s thermoforming service revolve around its precision, expertise in managing graphic deformations, ability to create custom molds, and comprehensive, customer-oriented approach to project management.